Venturi vacuum pumps

All intermittent gripping operations, i.e. which do not last for complete cycle of the machine.

Advantages:

. Consumption only when needed, results in low air consumption.

. Installation very close to the suction pads.

. Suction flow rate and vacuum level optimized to each individual requirement.

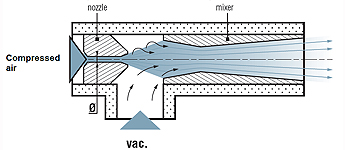

Using the «venturi» effect :

Using the «venturi» effect :

.jpg)